H-E Parts Whitepaper Newmont Crusher Liner Performance

Newmont Ahafo gold mine located in Ghana operates Metso 54×74 primary and MP800 secondary crushers and were experiencing excessive wear […]

Read MoreBIRRANA™ ENHANCED 930E WHEEL GROUP PERFORMANCE

Anglo American Los Bronces (Los Bronces) operates one of the largest copper mines in the world and is located in […]

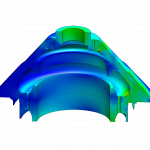

Read MoreIMPROVING CONE CRUSHER HEAD DESIGN AND PERFORMANCE

A NSW gold and copper mine were experiencing premature failures of its OEM supplied MP1000 heads, due to cracking of […]

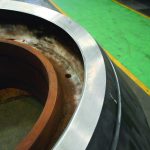

Read MoreMP1000 HEAD REPAIR

At a Western Australian iron ore mine, a customer had a major internal crack (linear indication) in the head of […]

Read More789C ENGINE SUPPLY AND PERFORMANCE

A customer with a fleet of 789C haul trucks required a replacement engine with minimal lead time. Aiming to minimize […]

Read MoreBAFFLED TANK FOR MORE EFFICIENT COOLING

A mining services provider, approached H-E Parts and asked them to address the reliability of their OEM supplied aftercooler. The […]

Read MoreIMPROVING METSO GYRATORY TONNAGE PERFORMANCE

First Quantum Minerals Limited (FQML) Kansanshi mine-site located in Zambia, were experiencing various issues with their OEM supplied mantles not […]

Read MoreBirrana™ Wheel End Technology Extends Life And Lowers Total Cost Of Ownership

A surface coal mining company in Powder River Basin, Wyoming saw H-E Parts present at Rocky Mountain Master Mechanics Association […]

Read MoreTIMELY SUPPLY TO MEET MAINTENANCE DEMANDS

A major issue in the mining industry is downtime and the costs associated with it. At H-E Parts, we understand […]

Read MoreD10T NOSE CONE ASSEMBLY SUPPLY

A major mining company in the Bowen Basin region of Queensland, Australia was experiencing process failure that resulted in significant […]

Read More