Improved Aggregate Particle Shape

In a NSW aggregate quarry, the customer used a portion of the materials produced for their concrete production business, thus requiring precise […]

Read MoreMantos Copper Relocation Project

Resourceful, Reliable with a Global Reach It is no small feat when a customer needs mining equipment transported across the […]

Read MoreOn-Site Service team exceeds expectations

H-E Parts International (H-E Parts) offers specialized maintenance services for all your minerals processing equipment and components. H-E Parts offers […]

Read MoreMP1000 Counterweight Assembly Repair / Upgrade

At a Western Australian gold mine the customer had an ongoing issue with the counterweight assemblies within their MP1000 crushers, not lasting […]

Read MoreUnique Approach to Plant Upgrade

At a sand loadout station located near the mouth of the Brisbane River in Queensland, H-E Parts was invited to submit a […]

Read MoreH-E Parts Outstanding Service Delivery

BHP Mt Arthur Coal (BHP) required an industrial radiator supplied at short notice for their Caterpillar D11T dozer, due to the inability […]

Read MoreContinuous Improvements on customers TC51 Cone Crusher Performance.

Western Areas Forrestania Nickel Project (Western Areas) located in Western Australia, were experiencing excessive wear and insufficient liner life in […]

Read MoreMulti-combination cooling pack

A family owned and operated trucking company in Australia were looking for a solution to reduce overheating issues experienced with […]

Read MoreImproving MP1000 Cone Crusher Performance

Newmont Boddington (Boddington) is a mine-site located in Western Australia, producing gold and copper concentrate. Boddington contacted the H-E Parts […]

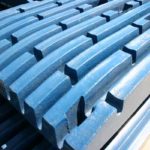

Read MoreIMPROVING C160 & C200 JAW CRUSHER PERFORMANCE

BHP Area C located in the Pilbara region of Western Australia, operates Metso C160 and C200 jaw crushers as its […]

Read More