Improving MP1000 Cone Crusher Performance

Newmont Boddington (Boddington) is a mine-site located in Western Australia, producing gold and copper concentrate. Boddington contacted the H-E Parts team when their OEM supplied liners for their Metso MP1000 secondary crushers weren’t lasting as long as expected. The initial expectation of the liners was that they would withstand 630,000 – 640,000 tonnes, but the OEM installed liners were only working to a life of 430,000 tonnes. To assist Boddington with improving their liners, H-E Parts engineers performed an on-site evaluation of the existing liners using innovative 3D laser scanning technology. Customising a liner based on each sites unique application allows H-E Parts to design and supply a liner that will perform well in the specific conditions and prolong the life of the liners on-site.

The objective of the Boddington liner development program was to reduce liner wear rates and extend time between liner change-outs. An added complication Boddington faced was extending specific liner sets to coincide with the majority of the liner change-outs, reducing the unnecessary costs associated with unexpected shutdowns.

Changes to crusher liners should be based on a combination of

the following;

- Requirements of individual site-specific applications.

- Maintenance requirements as they aren’t always compatible with metallurgy requirements (This often requires a balance between life and performance)

- Flow on effects on other parts of the plant

The data collected from the 3D laser scanning is sent to out dedicated team of engineers and analyzed in H-E Parts propriety ChamberVision™ and CrusherVision™ software, enabling our engineers to predict liner shape through the full design life. Liners are designed and tested with ChamberVision™ wear simulation. This propriety chamber design and analysis method allows for accurate benchmarking and performance estimates. ChamberVision™ allows performance of site-specific designs

to be tested pre-installation without prototyping, minimizing

the risk of unexpected issues before liners are even cast.

CrusherVision™ advanced crusher model simulation software

provides predictions of:

- Throughput

- Power draw

- Prediction of crushed product distribution

- Scenario testing to estimate the effects of changing machine parameters such as speed and eccentric throw

- Design-stage analysis tools to prevent issues such as chamber packing and stop start feeding issues.

By combining the capabilities of the CrusherVision™ and ChamberVision™ software, the H-E Parts team can accurately predict crusher performance at all points in the liner life. Preinstallation “testing” of profiles using H-E Parts simulation software minimizes risk. Ongoing monitoring of crusher

operational and wear performance ensures that changes in conditions are reflected in updated designs. Once the initial designs have been validated, H-E Parts applied site-specific demand management procedures to assist

Boddington in determining the most cost-effective liner management policy. A tailored approach allows H-E Parts to ensure that liner management policies are compatible with other maintenance requirements, whether that is isolated to a single crusher or the processing plant as a whole.

STAGE ONE

In stage one of development H-E Parts engineers improved the liner material on three of the Metso MP1000 secondary crushers to increase the liner life to coincide with all the secondary crushers on-site. The material change to the secondary crushers improved liner life by 23% when compared to the previously installed OEM liners.

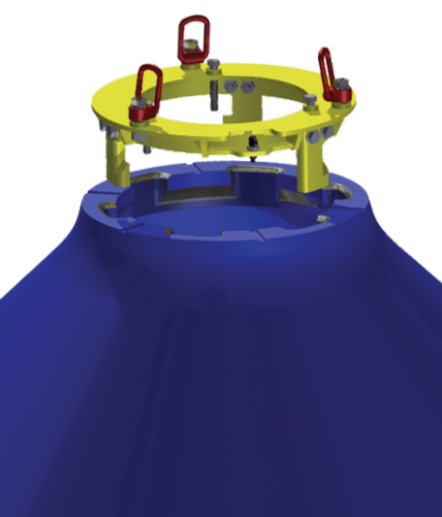

The added benefit of using H-E Parts proprietary CME™ crusher liners, is that they are designed for use with H-E Parts LockLift™ safety lifters, which Boddington have taken advantage of. The LockLift™ safety lifter provides the safest means available to remove and replace crusher liners. This allows the liner to be lifted through the center hole of the mantle after the head nut is removed. All styles utilize a jacking arrangement to separate the head and mantle before lifting. This guarantees a fully controlled lift takes place, while ensuring the lifting gear is not overloaded by lifting the head along with the liner. By removing the need to weld on lifting lugs, H-E Parts can provide customers with a safe, cost effective solution that also reduces

mantle change times.

STAGE TWO

With the successful improvements in stage one, Boddington engaged H-E Parts again to improve the liner profile cavity across all secondary crushers to ensure consistent performance between sets over time. When improving the liner profile cavity, H-E Parts engineers redistributed mantle weight to remain within the acceptable weight range. Too much weight overall can cause internal havoc on parts such as cracking and premature failure of the sockets, socket liners and the main shaft.

The material improvements in stage one and the profile cavity improvements in stage two have led to an increase liner life of above 772,000 tons (700,000 tonnes) in some cases. The average liner life across the six crushers is now regularly above 661,000 tons (600,000 tonnes), with more recent forecasts suggesting that the current stretch target of 794,000 tons (720,000 tonnes) will be achievable on most machines through continuous improvement.

FEED PERFORMANCE

The stage two analysis results found that the feed performance of the Metso MP1000 crushers were heavily influenced by the number of operating parameters which affected optimal efficiencies being achieved. H-E Parts technical account managers recommended to operate the crushers in choke fed mode as well as checking and adjusting the CSS (closed side setting) daily as per industry best practice. This resulted in the following:

- Start stop event occurrences were reduced, extending mean time between faults from 47 minutes to 120 minutes

- Under normal operating conditions, secondary crusher power targets were increased from 148 to 160 amps to ensure the crushers were in fact operating in choke fed mode

- During periods when crushed ore demand is low, crusher power targets were reduced from 160 to 130 amps, ensuring choke feeding was still occurring.

- Preventing recirculation and promoting consistent and efficient crushing due to CSS calibration.

CONCLUSION

Improving the liners performance for the Metso MP1000 has allowed Boddington to achieve a 49% increase in tonnage over the life of the liners when compared to the OEM’s initial liners. Due to the continued success with the MP1000 liner improvements, Boddington have awarded H-E Parts multiple long-term contracts for not only their secondary, but also their primary gyratory crusher concaves and mantles.