Timely Turnaround for Equipment at a Diamond Mine

A diamond mine in Northern Canada was in need of a remanufacturing partner that could work with a short window of economic transportation time. The mine is accessible through the world’s largest heavy haul ice road for eight to ten weeks, beginning in late January. This makes the logistics of receiving mine challenging.

Our customer prefers component delivery during winter to avoid costly air freight expenses. H-E Parts has the ability to receive components, tear down, quote, and repair to like new condition in the appropriate window to meet the ice road opening. Additionally, the customer works with our production team on teardowns and subsequent remanufacturing to get finished products built to exact specifications at a competitive price.

Annually, H-E Parts delivers haul truck, wheel loader, and dozer solutions to the customer in a tight window. Solutions include:

KOM 830E Haul Trucks

- 787 DC Electric Wheel Motors

- Birrana™ Enhanced Front Wheel Groups

- Front Suspensions

- Rear Suspensions

KOM HD785 Haul Trucks

- Final Drives (on 785-7 Equipment)

- Rear Axles (on 785-5 Equipment)

KOM WA900 Wheel Loaders

- Front Axles

- Rear Axles

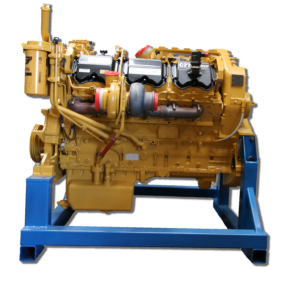

CAT D10T Dozers

- StaTerra Power™ C27 Engines

- Transmissions

- Ripper Cylinders

H-E Parts’ Mining Solutions, Engine Solutions, and Dom-Ex teams work collaboratively to ensure engine and complete drivetrains perform as expected and to the best standards possible through shared technology, information and innovations.

In addition to price and on time delivery, our customer values innovation and total cost of ownership.

Birrana™ Enhancements

Our Birrana™ enhanced wheel groups provide customers with a lower total cost of ownership. H-E Parts proprietary Birrana™ enhancements include:

- The Birrana™ control fit wheel bearing system, which includes flexible spacer, hardened spacer, custom bearing design and specifications, and preload adjustment

- Birrana™ contamination control which includes isolation seals, contamination guards, and contamination kits

- Birrana™ brake wear gauge allowing easy and fast brake wear measurement, reduced downtime, and improved safety

Utilizing H-E Parts wheel groups has provided the customer with extended service life and increased maintenance planning accuracy through shorter repair times and increased service exchange availability.

Staterra Power™ Enhancements

Our StaTerra Power™ engines are built to outperform the competitor. All engines are offered in both standard specifications and with customer requested options. Each engine comes with an industry standard warranty. Our rebuild process includes:

- A teardown report with the condition of major components

- In-House Machining to ensure performance and life extension for components

- Major components NDT tested by certified technicians

- Cylinder block work includes inspection of 50 critical areas, machining and optional spray welding to restore deck height

- Cylinder Block machining restores to specification the block deck surfaces, liner bores, and bearing bores

- Crankshaft is balanced using the latest processes and customized equipment

- Match Balanced reciprocating assemblies (Rod, Piston and Pin)

- Restoration of original lift and duration on camshafts

- A Dyno test ensures it meets Peak Horsepower and Peak Torque

- A final 26-Point inspection prior to delivery

All work was completed in-house. The ability to manage the complete process and manufacture the component provided the customer complete transparency of the scope of work, components remanufactured back to zero hours, expedited service delivery to meet their transportation needs, and a lower total cost of ownership over purchasing a new component.

Since 2018, H-E Parts has delivered over 30 components to this customer within the required delivery schedule.