{{cart_parts.length}}

×

Thanks for contacting us!

Request a Quote

You have just added part(s) # {{just_added}}.

0 Parts Added.

Parts in Cart:

| Division | Equipment Type | Make | Model | H-E Parts # | OEM Part # | Description | Availability | Delete | |

|---|---|---|---|---|---|---|---|---|---|

|

Division:

{{part.division[0]}}

×

|

Equipment Type:

{{part.equipment_type[0]}}

|

Make:

{{part.make[0]}}

|

Model:

{{part.model[0]}}

|

H-E Part #:

{{part.he_part_num[0]}}

|

OEM Part #:

{{oem_part_num}}

|

Description:

{{description}}

|

Availability:

|

× |

Thanks for contacting us!

We will get in touch with you shortly.

- Mobile Mining Solutions

- Hydraulic Cylinders

- Front and Rear Suspensions

- Steering and Hoist Cylinders

- Underground Mining

- Underground Mining Parts & Components

HEPI EnhancementsCan’t find what you’re looking for?With thousands of items in our H-E Parts inventory, we likely have what you need.

Contact Us

Contact us today for availability and expert assistance. - Fixed Plant

- Site-Specific Crusher Liners

- Jaw Crusher Liners

- Cone Crusher Liners

- Gyratory Crusher Liners

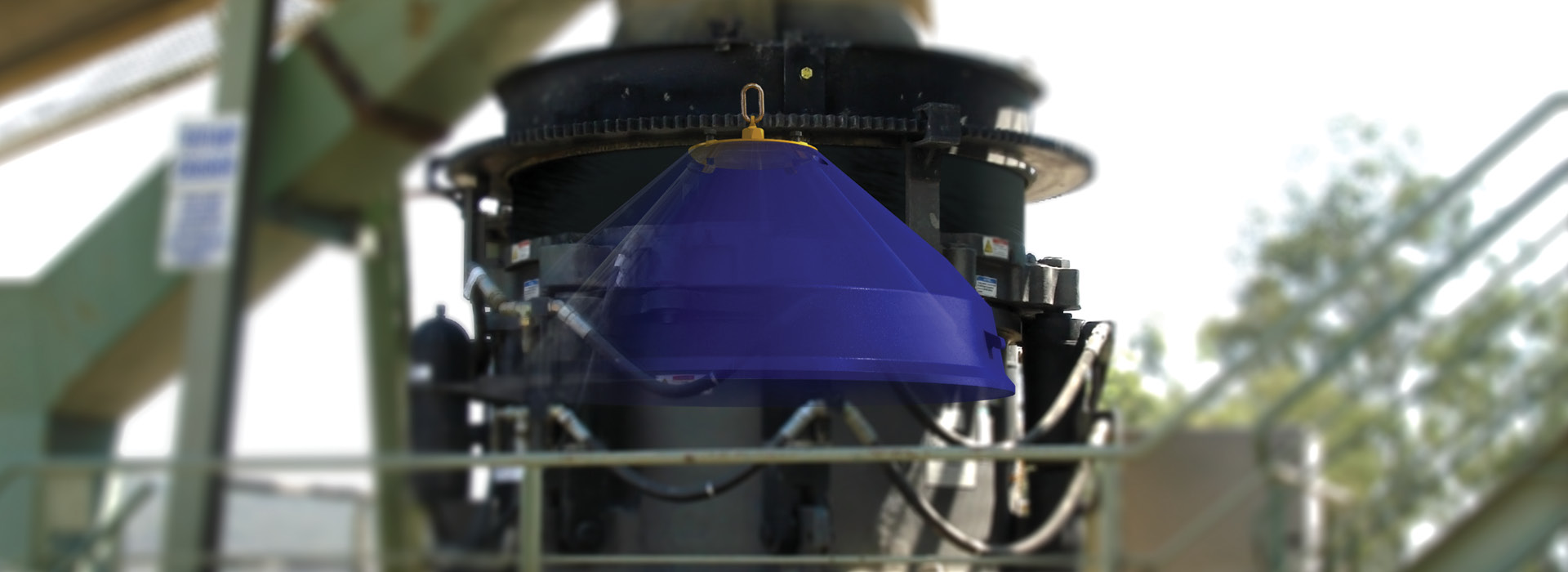

- Crusher Safety Solutions

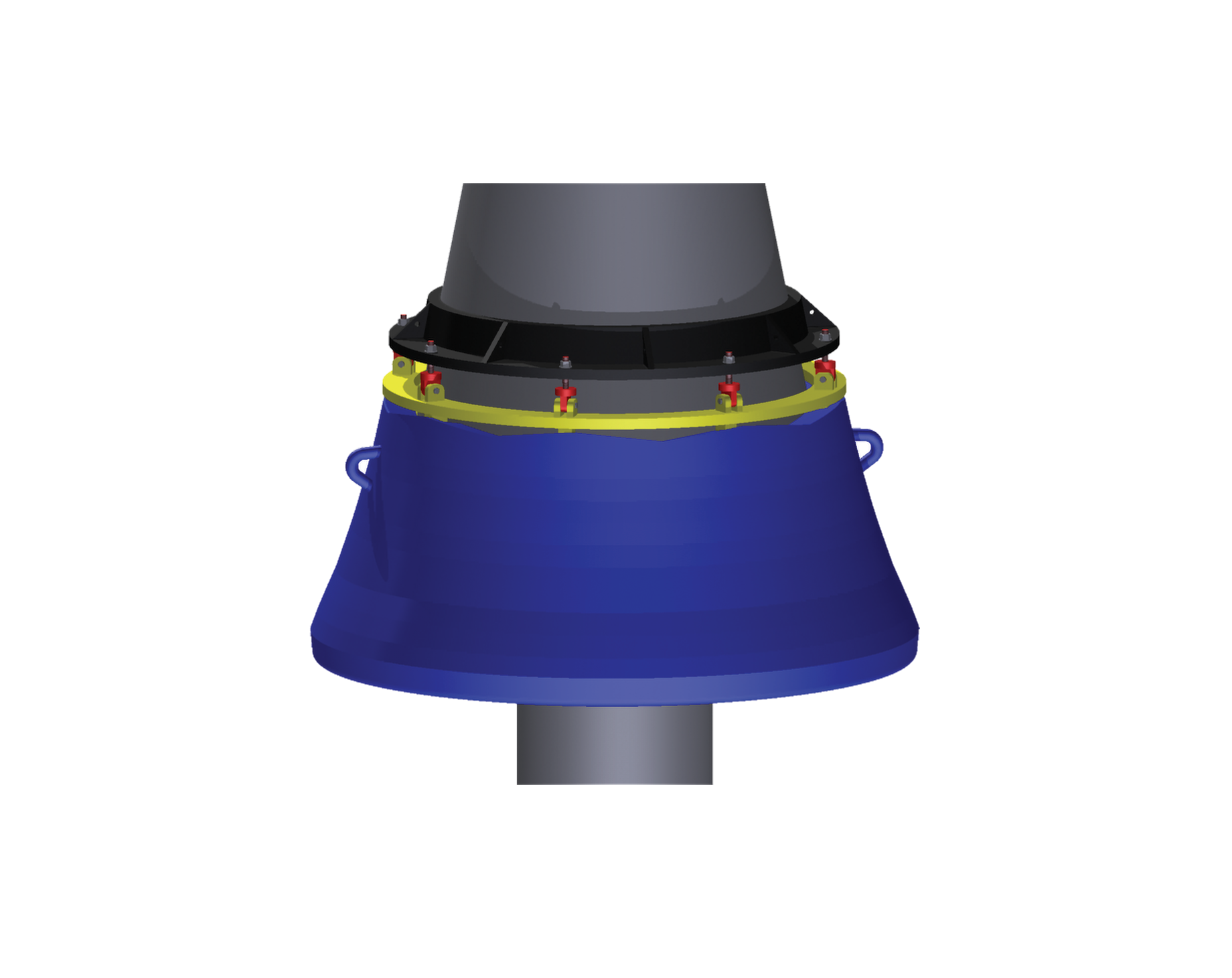

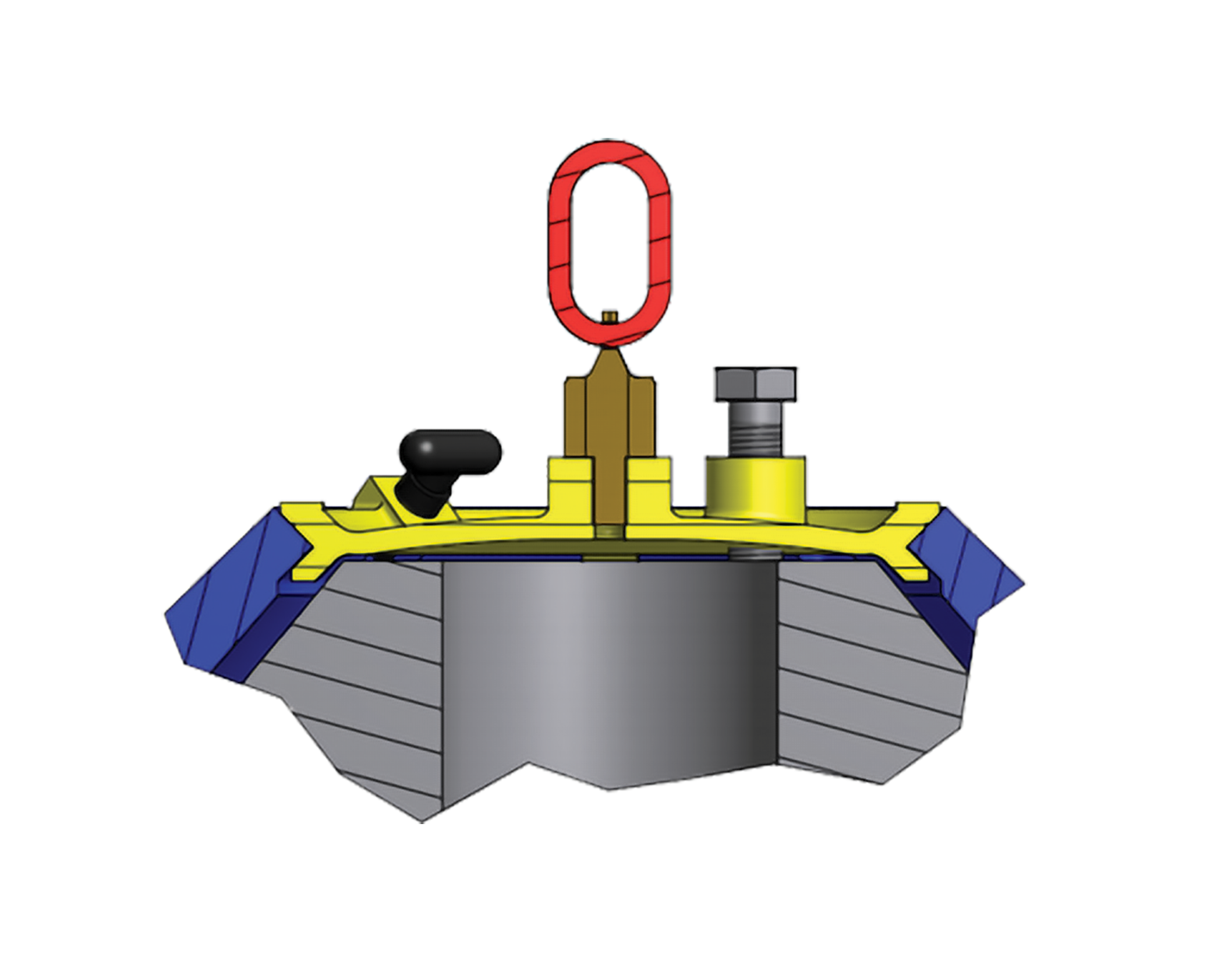

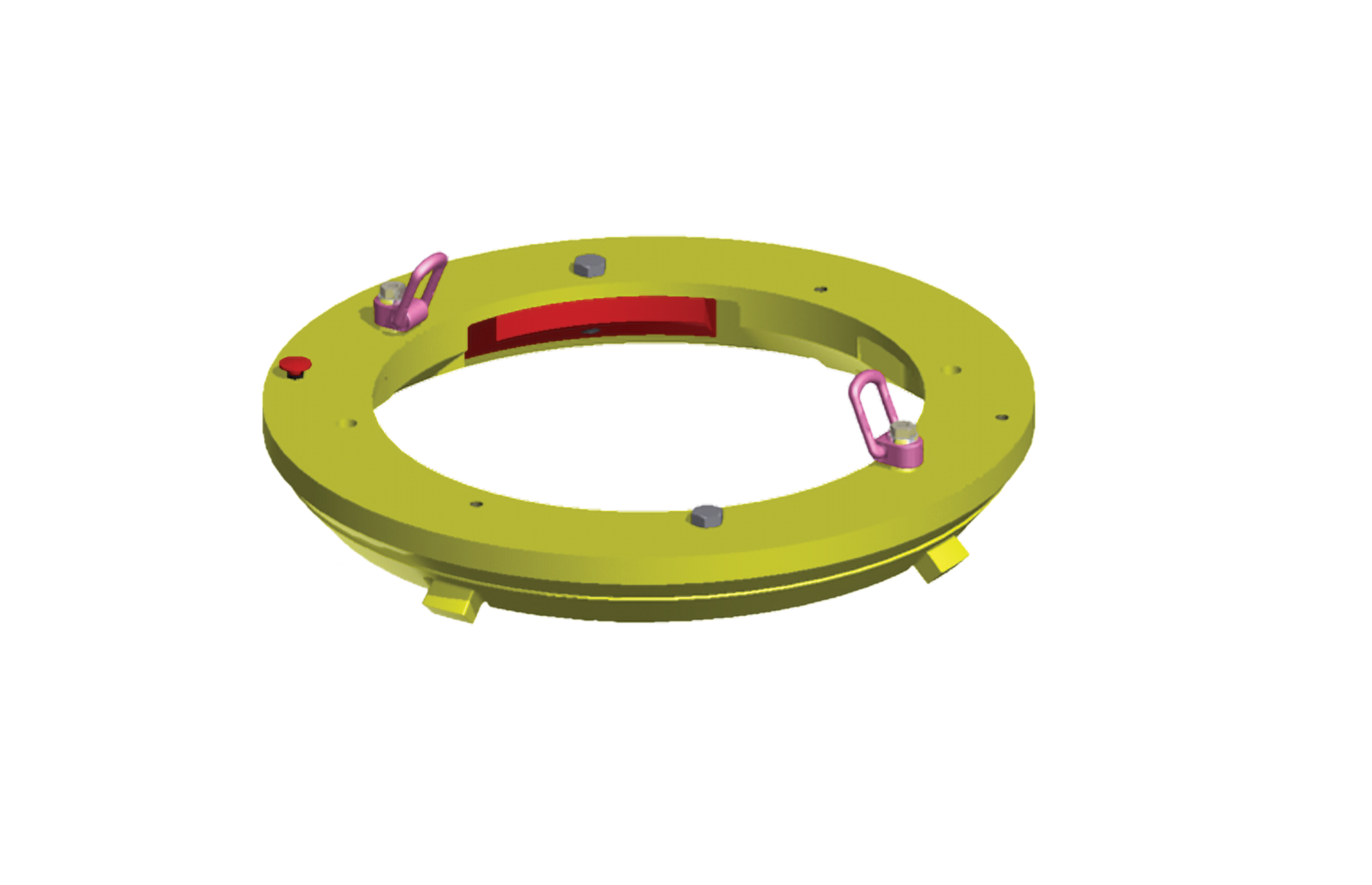

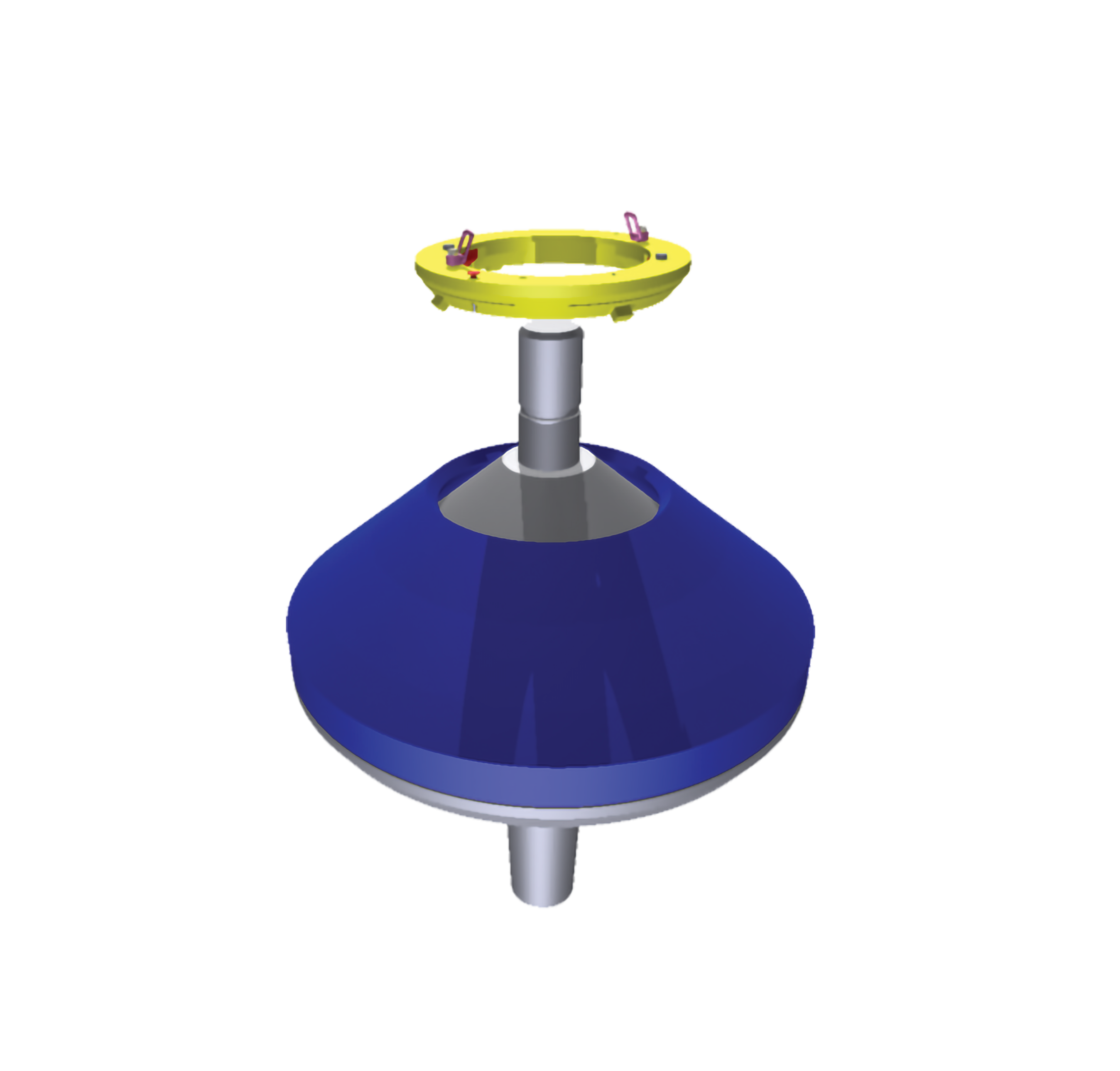

- Locklift™ Mantle Lifting System

- Safe-T-Lift™ System

Can’t find what you’re looking for?With thousands of items in our H-E Parts inventory, we likely have what you need.

Contact Us

Contact us today for availability and expert assistance. - Parts Inventory

- Contact Us