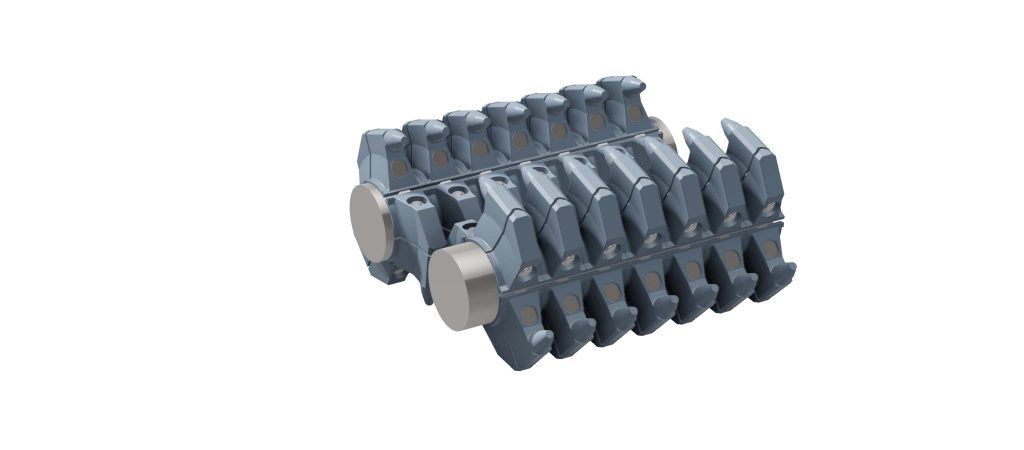

IMPROVED SIZER SEGMENT TEETH LIFE

Roy Hill Iron Ore Mine located in the Pilbara region of Western Australia operates Abon mineral sizers in its processing facility and were experiencing excessive wear and insufficient teeth life in their secondary sizers. H-E Parts approached Roy Hill with a proposal to offer a cost-effective solution to their on-going issues associated with

STAGE 1 – IMPROVED MATERIAL

H-E Parts technical specialists conducted a detailed wear analysis of the application and initially recommended improving the material selection of the sizer teeth whilst maintaining the OEM design, as this would allow a benchmark for comparison. Running in direct comparison to the OEM supplied sizer teeth, the H-E Parts sizer teeth lasted approximately 25% longer.

STAGE 2 – NEW IMPROVED MATERIAL AND DESIGN

In-line with H-E Parts philosophy of continuous improvement and wear management principles, H-E Parts then offered a further advancement to the initial product trailed at Roy Hill. This saw not only a further material